.webp)

Printing Breathable PE Film

Printing Breathable PE Membrane

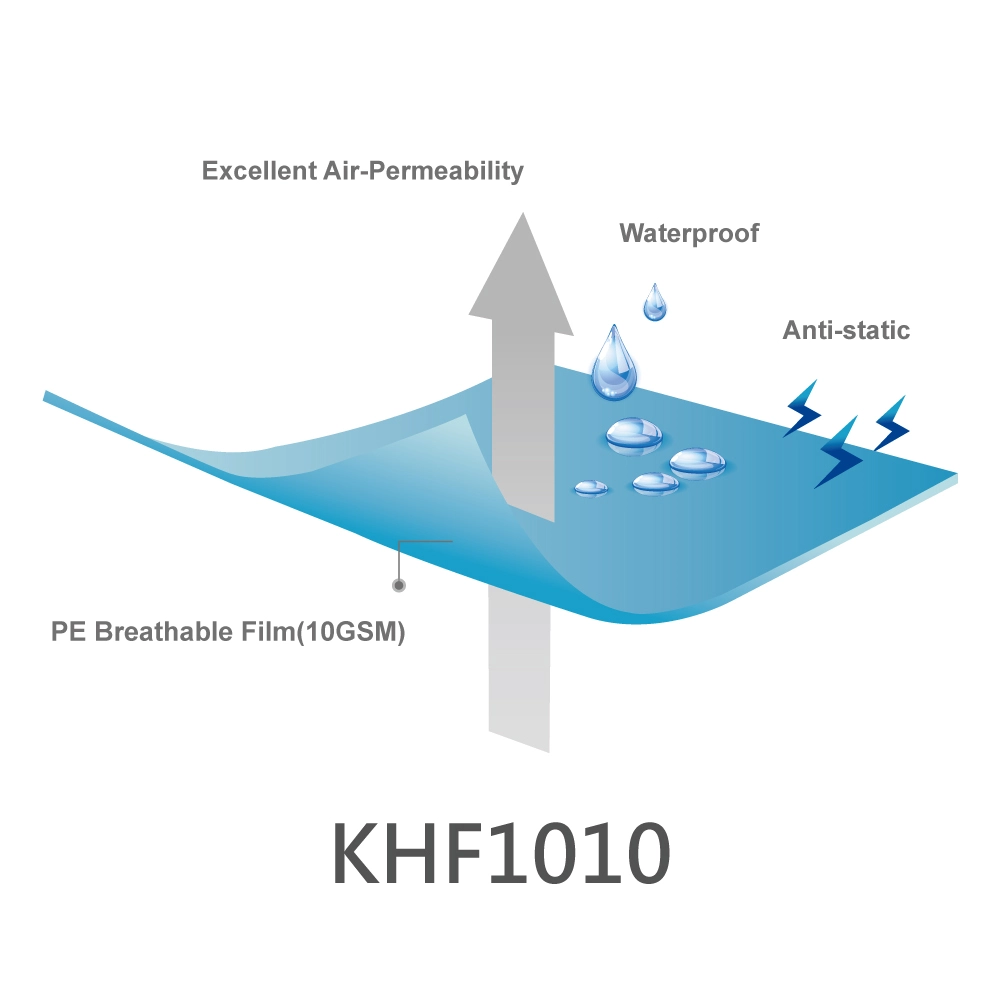

Printing Breathable Polyethylene Membrane is a versatile material used for packaging and diaper back layers, offering a variety of advantages, including lightweight, printability, moisture resistance, oxidation resistance, and a smooth surface. It not only provides excellent product protection but also ensures accurate reproduction of shape and color. This material is made from colorless, odorless, and non-toxic polyethylene membrane, widely used in packaging bags, food bags, diaper back layers, and more.

Due to the inert nature of polyethylene, achieving high-quality prints on its surface can be challenging, thus requiring special treatment for optimal results. Our Printing Breathable Polyethylene Membrane utilizes advanced ink printing technologies, specifically designed to provide superior clarity and adhesion on plastic membranes.

Our printing process combines high-quality pigments to produce vibrant colors with strong adhesion. This fast-drying ink, when printed on a gravure rotary press, ensures high printing efficiency, excellent durability, and vivid colors, making it ideal for various packaging applications, including precise color matching and layout for breathable, waterproof diaper back layers.

Whether you are looking for moisture and oxidation-resistant packaging or need a breathable, comfortable diaper back layer, our Printing Breathable Polyethylene Membrane is the perfect solution.

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

Key features include:

- Excellent breathability: The breathable structure effectively expels moisture and heat, keeping the internal environment dry.

- Superior waterproof performance: It effectively blocks external moisture, providing reliable protection.

- Moisture and Oxidation Resistance: Offers excellent protection against moisture and oxidation, extending product shelf life.

- High Color and Shape Reproduction: High-quality printing techniques ensure accurate reproduction of product design.

- Eco-Friendly Material: Colorless, odorless, and non-toxic, making it suitable for food packaging.

- Special Treatment for Printing: Utilizes flexographic, gravure, and screen printing technologies to ensure clear, durable, and long-lasting prints.

- Fast Drying: Uses high-viscosity, quick-drying volatile inks, enhancing production efficiency with fast and convenient printing.

| Name | Specification |

| Material | Polyethylene |

| Weight | 10 - 100 gsm |

| Width | 80mm - 2000mm |

| Length | 2000M |

| Surface Treatment | Up to 4 colors printed will allow to imitate multiple colorful print |

| Application | Packing, Industrial, Medical, Hygiene, Agricultural |

Company Profile

Kae Hwa Industrial is a professional factory, founded in 1964, specializing in the production of breathable waterproof membrane and textile in Taiwan. Our main application of the product is medical fabric (AAMI L4), Industrial protective fabric (Type 4B 5B 6B), Hygiene fabric of diaper, napkin, underpad backsheet, construction fabric of house wrapping, agricultural fabric for mulch, consumer fabric of desiccant, dehumidifier, deodorant, warm pack packaging and GRS-certified outdoor functional fabric for outdoor jackets.

We are certified many certification of ISO 9001:2015, 14001:2015, 14064-1:2018, Halal and GRS to improve our products.

Your Choice, Our Responsibility