Why You Need "Holes" in Your Waterproofing: The Thermodynamics of Microporous Membranes

For centuries, the definition of "protection" in materials science was binary: a material was either open to the air or sealed against the elements. From the earliest use of animal hides to the widespread adoption of polyethylene plastics in the 20th century, the goal was absolute isolation. However, this philosophy of total sealing has revealed a critical flaw in modern applications. Whether in the building envelope of a skyscraper, the delicate root system of a crop, or the micro-environment of a desiccant package, trapping moisture is often more destructive than letting water in.

This comprehensive guide explores the paradigm shift towards Microporous Breathable Membranes. We deconstruct the physics of Moisture Vapor Transmission Rates (MVTR), the chemistry of specialized mineral compounding, and the advanced In-Line Lamination technologies that make this paradox possible. By analyzing the "Invisible Pore," we reveal how precision engineering solves the universal challenge of moisture management across construction, agriculture, packaging, and medical hygiene sectors.

The Waterproofing Trap: When Protection Becomes Destruction

In the collective imagination, a waterproof material is a solid wall. We visualize a raincoat, a plastic tarp, or a rubber boot—barriers designed to repel water by creating a hermetic seal. While effective at blocking rain, these "monolithic" barriers create a secondary problem that is often invisible until the damage is done: they trap vapor.

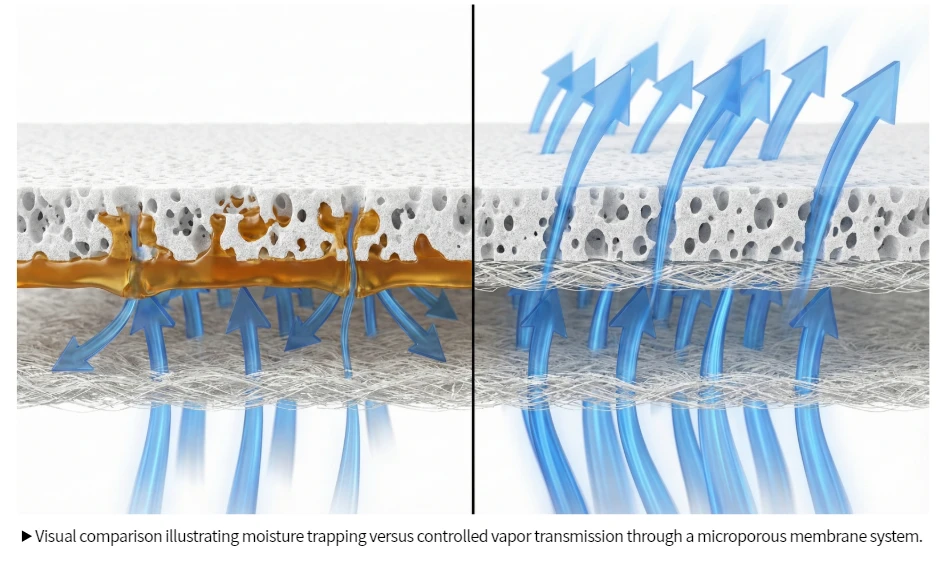

In thermodynamics, moisture moves from areas of high concentration (warm, humid) to areas of low concentration (cool, dry). When we wrap a house, a field, or a human body in a non-breathable plastic sheet, we disrupt this natural equilibrium. The vapor generated internally—whether from household activities, soil evaporation, or perspiration—hits the impermeable barrier and condenses.

This trapped moisture creates a "micro-climate" of destruction:

- In Construction: It leads to interstitial condensation, rotting timber frames and degrading insulation.

- In Agriculture: It creates anaerobic soil conditions that "cook" root systems and encourage pathogens.

- In Functional Packaging: It renders desiccant sachets ineffective. A non-breathable wrapper prevents the active ingredient from absorbing moisture, while a low-quality barrier risks leaking corrosive chemicals onto the product.

The solution to this universal problem requires a material that can distinguish between water in its two most common states: liquid and gas. This is the domain of Microporous Film Technology—the science of putting billions of holes in a waterproof wall.

The Physics of the "Perfect Hole": Scale and Tension

How do you manufacture a barrier that stops a storm but passes a vapor molecule? It is not magic; it is a precise application of fluid dynamics and geometry. The technology relies on leveraging the massive size differential between liquid water and water vapor, combined with the force of surface tension.

The Mathematics of Scale

To understand the engineering challenge, we must look at the specific dimensions involved in the molecular world.

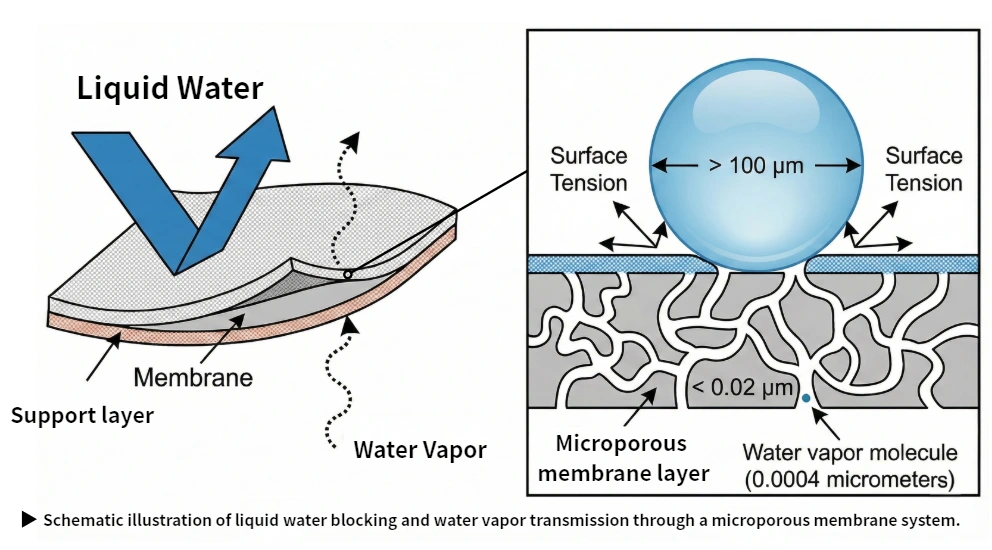

- The Liquid Threat: A typical raindrop or liquid water droplet is massive in relative terms, ranging from 100 microns (µm) to 3,000 µm in diameter. Even a fine mist droplet is rarely smaller than 50 µm.

- The Vapor Solution: A molecule of water vapor (moisture) is distinctively smaller, measuring approximately 0.0004 µm.

- The Microporous Solution: High-performance membranes are engineered with pores roughly 0.1 µm to 10 µm in diameter.

This creates a physical sieve. The pore is thousands of times larger than the vapor molecule, allowing it to drift through via diffusion. However, the pore is significantly smaller than the smallest water droplet. It is akin to throwing a basketball at a chain-link fence; the air passes through, but the ball is physically blocked.

Surface Tension: The Invisible Shield

Size is only half the battle. If you push hard enough, you can force a large object through a small hole. However, liquid water possesses high surface tension. This cohesive force makes water molecules cling together tightly, forming a spherical droplet rather than spreading out.

When a raindrop hits a high-quality microporous film, the surface tension prevents the droplet from "breaking" its shape to squeeze through the tortuous microscopic paths. Unless the water pressure (Hydrostatic Head) exceeds the material’s critical limit, the droplet bridges across the pore opening without entering it. This allows the material to achieve high water column resistance while remaining completely open to airflow.

Manufacturing The Invisible: How Microporous Films are Born

Creating these specific pores requires a sophisticated manufacturing process known as Casting Film Extrusion coupled with MDO (Machine Direction Orientation) stretching. This is a far more complex process than simple blown plastic film.

The Role of Specialized Mineral Particles

The "holes" are not punched mechanically; they are created through stress-induced void formation.

- Compounding: The process begins by mixing a polyolefin resin (Polyethylene PE or Polypropylene PP) with fine, specialized mineral particles (such as Calcium Carbonate).

- Extrusion: This mixture is melted and extruded onto a chilled casting roller. Precision Casting Technology is essential here to ensure extreme uniformity in thickness, with tolerances as tight as ±0.01 mm. This precision is critical; variable thickness would lead to variable breathability.

- Stretching (MDO): The solid film is then heated and stretched rapidly in the machine direction. Because the polymer is elastic but the mineral particles are rigid, the polymer pulls away from the particles.

- Micro-Void Creation: This separation creates microscopic cavities (pores) around each particle. These are not straight tunnels but complex, "tortuous paths" that trap water but guide vapor.

The Lamination Challenge: Solving the "Glue Problem"

A microporous film is technically functional on its own, but it is often too thin to withstand the rigors of a construction site or a farm field. It must be bonded to a protective fabric (nonwoven).

Traditional lamination uses adhesive glue. The problem? Glue clogs the pores you just worked so hard to create. The industry standard for premium membranes is In-Line Lamination Technology. By bonding the microporous film to a nonwoven substrate immediately after casting—while the polymer is still semi-molten—manufacturers can achieve a thermal bond without the use of solvents or heavy adhesives.

- Result 1: Maximum Breathability (No glue blocking the pores).

- Result 2: Superior Durability (Integral bond prevents delamination).

- Result 3: Sustainability (Solvent-free process).

Industry Applications: One Science, Four Solutions

The versatility of microporous technology allows it to solve critical failure points across widely different industries. While the specific product names may vary, the core physics remains the same.

Construction: The Breathing Building

Modern energy codes demand airtight buildings to retain heat, but this often leads to "Sick Building Syndrome" where moisture is trapped inside walls.

- The Threat: Moisture from cooking and breathing migrates through drywall. When it hits cold exterior sheathing, it condenses. This "interstitial condensation" rots wood and fosters black mold.

- The Solution: Breathable roofing underlayments and wall wraps function as a Weather Resistive Barrier (WRB). They stop wind-driven rain from entering the structure (protecting insulation) but have a high MVTR to let the building "exhale" trapped moisture, preserving the structural integrity of the home.

Agriculture: The Living Soil

Soil is a living ecosystem that breathes. Traditional "plasticulture" (black plastic mulch) suffocates soil, creating an anaerobic oven that kills beneficial bacteria and cooks crop roots.

- The Threat: Root heat stress and lack of oxygen lead to poor nutrient uptake and lower yields.

- The Solution: Breathable agricultural laminates provide a "living barrier." They are waterproof (to stop heavy rain from washing away fertilizer) and opaque (to block UV and stop weeds), but their breathability allows for gas exchange. This stabilizes soil temperature and oxygen levels, promoting a healthier root zone and higher crop yields.

Functional Packaging: The Kinetic Balance

In the world of desiccant sachets (silica gel, clay, or calcium chloride) and active packaging, the wrapper material determines the performance of the entire unit.

- The Threat: A desiccant sachet functions by absorbing moisture from the air through its packaging. If the packaging film is standard plastic, it blocks moisture entry, rendering the desiccant useless. Conversely, if the material is too porous (like simple paper), the saturated chemicals inside can liquefy and leak out, destroying the sensitive electronics, leather goods, or pharmaceuticals they were meant to protect.

- The Solution: Microporous film offers a "Controlled Transmission Rate." It allows high volumes of vapor to enter for rapid absorption but creates a superior liquid barrier to prevent any reverse leakage (keeping the gel or liquid trapped inside). It also prevents "dusting" (fine particles escaping), making the sachets safe for sterile or cleanroom environments.

Medical & Hygiene: The Comfort Factor

Perhaps the most sensitive application is direct contact with human skin.

- The Threat: In diapers, sanitary pads, or medical protective clothing, a non-breathable plastic backing causes heat buildup and skin maceration (softening of the skin due to moisture), leading to rashes and discomfort.

- The Solution: Advanced breathable films provide a "cloth-like" feel. They block bodily fluids and blood but allow body heat and perspiration to escape. This keeps the skin dry, maintains a healthy pH balance, and ensures comfort during long-term wear.

Beyond the Pore: Sustainability and Customization

The future of waterproofing is not just about performance; it is about responsibility. The era of disposable, non-recyclable plastics is ending. Microporous membranes, particularly those based on Polyolefins (PE/PP), offer a sustainable path forward.

The Monomaterial Advantage

Because advanced In-Line Lamination bonds PE film to PE/PP nonwovens without chemical adhesives, the resulting composite is often easier to recycle than multi-material laminates glued together. Leading manufacturers focus on solvent-free manufacturing, reducing Volatile Organic Compounds (VOCs) and energy consumption during production.

Tailored Performance

Not all "holes" should be the same size. Different industries require different transmission rates.

- High Breathability: Required for medical gowns or activewear where heat stress is a risk.

- Low/Medium Breathability: Required for construction vapor retarders where moisture release needs to be slow and controlled. By adjusting the stretching parameters during manufacturing, engineers can customize the MVTR from low ranges to high ranges, tailoring the "physics" of the film to the specific needs of the client.

The Intelligent Barrier: Your Next Step in Material Innovation

The concept of a "barrier" has evolved. It is no longer enough to simply block nature. The barriers of the future must be intelligent interfaces that manage the complex exchange of energy and matter between the inside and the outside.

Whether it is protecting the structural longevity of a family home, ensuring the harvest of a season's crop, or keeping a baby's skin dry and healthy, the mechanism is the same. It is the precise, engineered balance of the Microporous Membrane.

Kae Hwa Industrial has built its reputation on mastering this specific balance. With decades of manufacturing expertise and a commitment to innovation, we do not just manufacture films; we engineer the pores that let the world breathe. By combining precision casting, material science, and solvent-free lamination, we provide the "invisible skin" that modern industry relies on.

From BuildBreathe™ in construction to AgriGuard™ in agriculture and PackDry™ in packaging, our science is the foundation of your protection.

Don't just look for waterproofing. Look for the science inside the pore.

Tell us your challenge, and we will engineer the permeability.

FAQ

Q1: How do you ensure the "holes" don't leak under pressure?

A: This is determined by the Hydrostatic Head rating. While the pores allow vapor through, their microscopic size combined with the hydrophobic nature of PE/PP creates a high resistance to liquid water entry. We test our films to ensure they can withstand specific water column pressures depending on the application.

Q2: What is the difference between Microporous and Monolithic films?

A: Microporous films use physical pores for breathability and are created via stretching. They offer excellent airflow and are cost-effective. Monolithic films are solid, non-porous films that transport moisture via molecular diffusion through hydrophilic chains. Kae Hwa manufactures both types to suit different industrial needs.

Q3: Can these films be printed on?

A: Yes. Kae Hwa utilizes 4-Color Printing Technology that can apply high-resolution branding and instructions directly onto the breathable film without clogging the pores or compromising the MVTR.