Upgrade from the Backsheet: How to Design Cooler and More Comfortable Diapers

Diaper Backsheet Solutions That Are Breathable, Leak-Proof, and Production-Ready

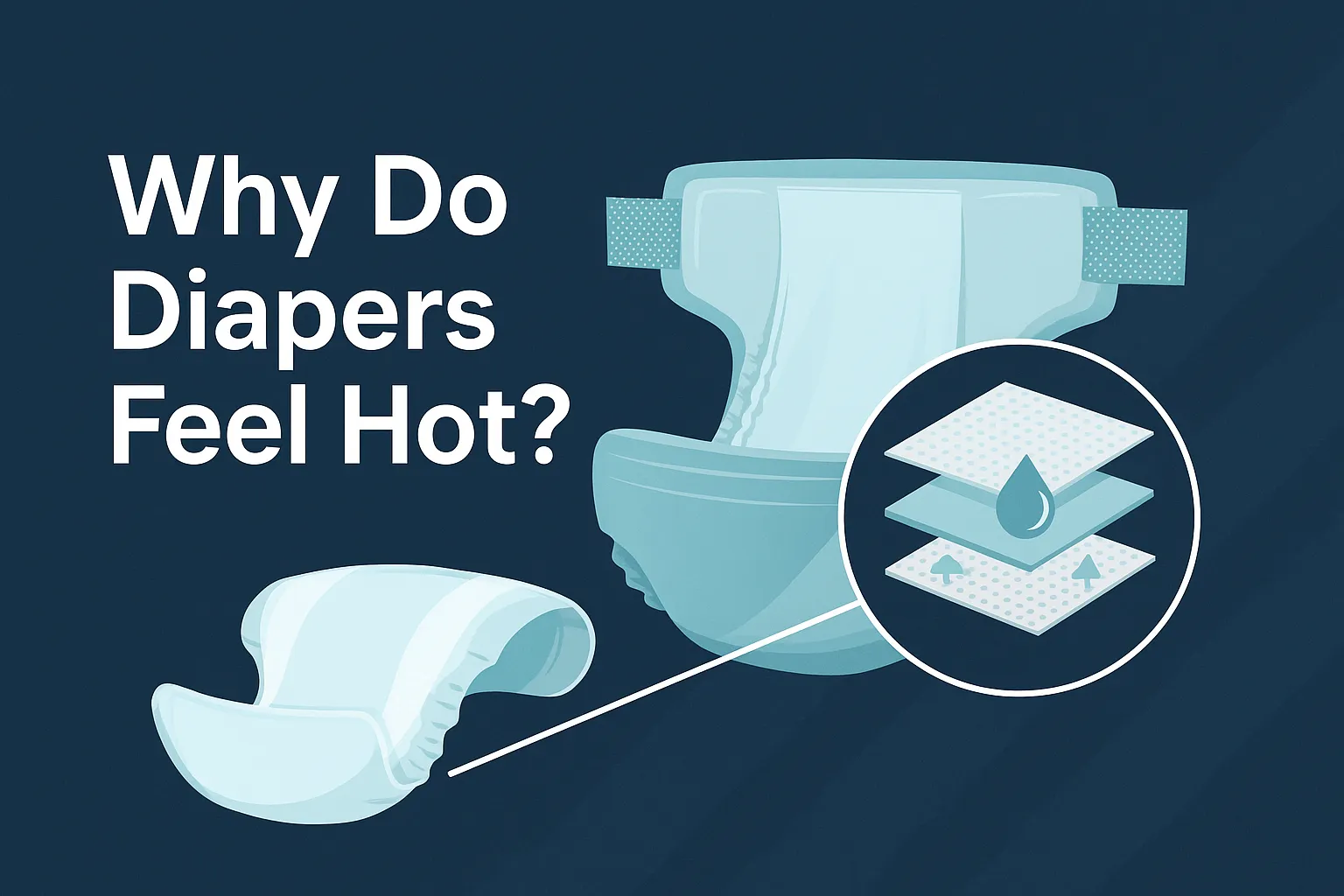

When developing disposable diapers, most brands prioritize absorbent core performance. However, discomfort such as heat and rash often originates from poor breathability in the diaper backsheet—the outermost layer of the product that directly impacts ventilation, comfort, and brand differentiation.

At Kae Hwa, we provide laminated diaper film solutions that combine a breathable microporous membrane with a soft nonwoven layer. These backsheet materials are engineered to improve comfort and appearance while supporting high-speed production and custom branding needs.

Why Diaper Discomfort Often Starts from the Backsheet

In hot and humid climates, many diapers with non-breathable plastic back layers trap moisture and heat inside. This can cause skin irritation, diaper rash, or discomfort for the wearer—especially babies or bedridden adults.

By using breathable diaper film made from microporous membranes, moisture vapor can pass through the backsheet while liquid stays sealed inside. When laminated with soft nonwoven fabric, this creates a diaper backsheet that feels gentle on skin, reduces heat retention, and enhances product comfort.

Laminated Structure for Stable, High-Quality Diaper Backsheets

Our breathable diaper backsheet material is a two-layer laminated structure:

- Microporous Diaper Film: Made from PE, this film includes micro-holes that allow vapor to escape while preventing liquid penetration. It ensures a dry, breathable environment for the wearer.

- PP Nonwoven Fabric: Adds a soft texture and supports multi-color printing for customized branding and product appearance.

Our materials are compatible with thermal lamination and PUR adhesive bonding. They are suitable for baby diapers, adult diapers, pull-up pants, and sanitary pads, and can be seamlessly integrated into high-speed automated production lines.

👉 Explore the Product: Breathable Diaper Backsheet Film

Upgrading the Diaper Backsheet: A Path to Product Differentiation

In a competitive hygiene market, brands are increasingly seeking to differentiate by enhancing comfort and quality. The diaper backsheet plays a vital role in achieving this goal.

By upgrading to our laminated breathable diaper film, you gain the following advantages:

- Improved breathability for cooler, drier wear—reducing rashes and discomfort

- Enhanced user experience and parent satisfaction

- Stable structure with excellent processability and printing flexibility

- Custom film thickness, color, and branding options for various market positions

Whether your brand focuses on high-end diapers or seeks to stand out with custom prints, our backsheet materials provide both functional performance and production scalability.

Create High-Quality Diaper Products with the Right Backsheet Material — Contact Us Now!

Kae Hwa specializes in manufacturing breathable diaper films and laminated backsheet materials designed for hygiene applications. We support custom orders, sample testing, and OEM development.

FAQ

Q1: What types of products can this diaper backsheet film be used for?

A: Our laminated backsheet material is suitable for baby diapers, adult diapers, training pants, and sanitary napkins.

Q2: Do you offer printing or branding customization?

A: Yes, we support multi-color printing, including reverse or surface printing, to meet various brand identity and design requirements.

Q3: Is there a minimum order quantity?

A: We offer flexible MOQs and can also provide sample rolls for lamination testing and early-stage development.