Microporous vs. Monolithic Membranes: Principles and Selection of Waterproof-Breathable Membrane Technologies

When "Waterproof" Is No Longer the Only Standard

Over the past fifty years, textile and material science has undergone a quiet but drastic revolution. Early raincoats or protective suits, while impermeable to water, were akin to wrapping the user in a plastic bag. Sweat and moisture were trapped inside, leading to severe discomfort and even heat exhaustion.

The "Holy Grail" of modern functional materials lies in solving a physical paradox: How do we block giant water droplets from entering while allowing tiny water vapor molecules to escape?

This is the battlefield of Waterproof Breathable technology.

With over 60 years of experience in this field, Kae Hwa Industrial has witnessed and driven the evolution of this technology. We have found that many procurement managers and product designers are often trapped in a fog of technical terminology. The most common confusion is: What exactly is the difference between Microporous and Monolithic membranes? And which one is right for my product?

This article strips away the marketing jargon to provide you with a comprehensive technical decision guide, covering microstructures, operating principles, and industrial applications.

Microporous Membranes — A Microscopic Miracle of Physics

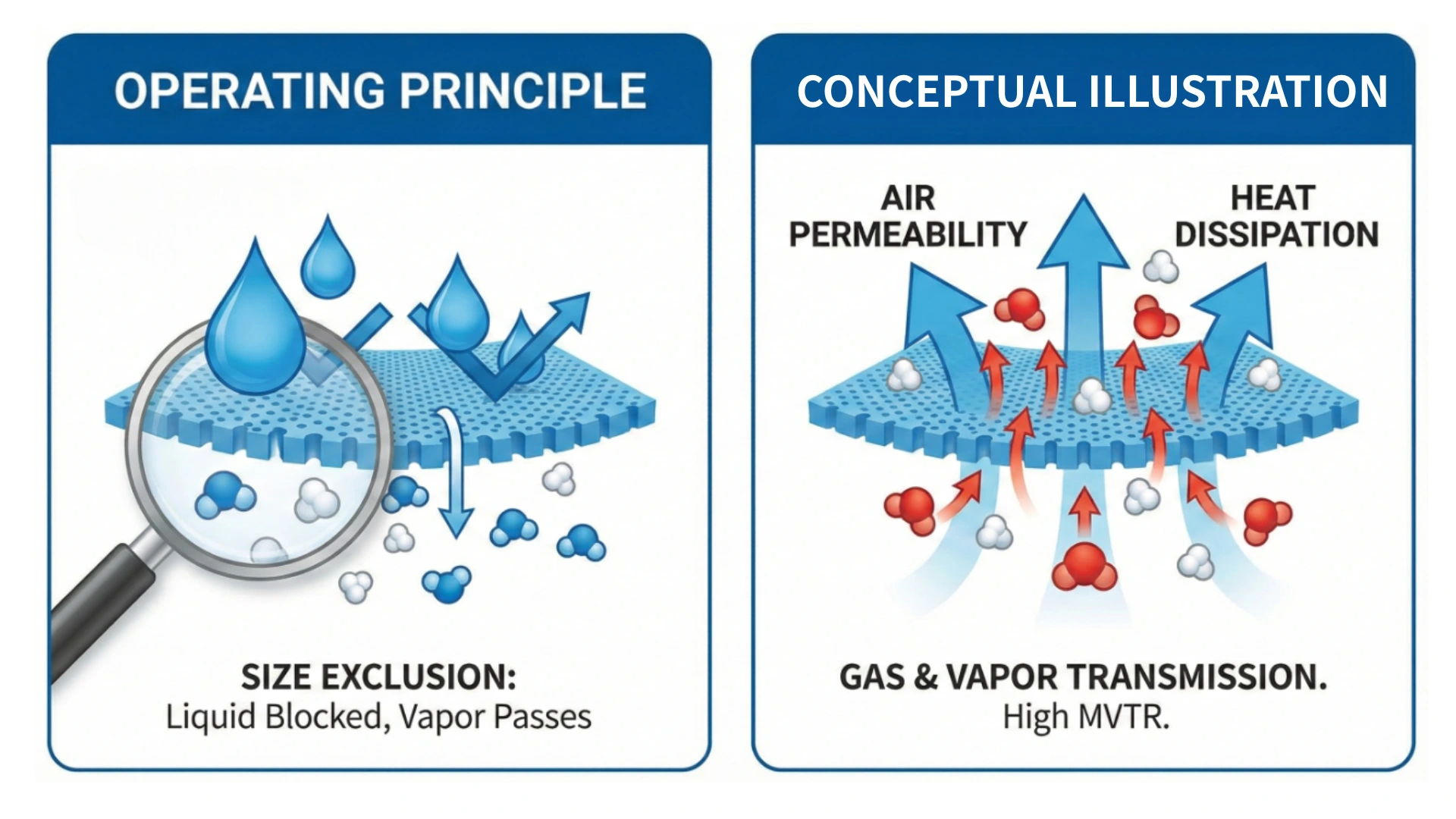

Operating Principle: The Nano-Scale Sieve

The core technology of microporous membranes lies in "size exclusion." Imagine a net filled with countless tiny holes created through a specialized stretching process.

- Blocking Water: The microporous structure effectively blocks the penetration of external liquids (such as rainwater or blood).

- Passing Vapor: Simultaneously, these pores are large enough to allow air and tiny water vapor molecules to pass through.

Kae Hwa Industrial's MicroBreath™ Series utilizes this physical structure to provide a reliable balance of waterproofing and breathability.

Core Advantage: Gas & Vapor Transmission

The advantage of microporous membranes lies in their Gas & Vapor Transmission capabilities.

In most designs, it offers Air Permeability and immediate heat dissipation, meaning hot air can be quickly expelled, reducing stuffiness. (Note: For applications requiring high hydrostatic pressure resistance, pore size may be adjusted, but excellent Moisture Vapor Transmission Rate (MVTR) is maintained.)

Monolithic Membranes — Chemical Intelligence

Operating Principle: The Molecular Relay Race

In stark contrast to microporous membranes, Monolithic membranes (such as Kae Hwa's AquaVene™ Series) appear smooth and dense, with absolutely no physical pores. Their breathability mechanism comes from Hydrophilic Polymer Chemistry.

These films operate on the principle of "Solid State Diffusion":

- Adsorption: Hydrophilic groups absorb water vapor molecules from the skin side.

- Diffusion: Water molecules are transferred along the polymer chain.

- Desorption: Finally, the moisture is released into the external environment.

Core Advantage: Ultimate Protection & Durability

- Absolute Barrier: With no physical pores, it maintains a structurally complete liquid barrier.

- Softness & Elasticity: Materials like TPEE endow it with excellent elongation and a soft touch, making it suitable for dynamic activities.

- Durability: The dense structure is resistant to detergent residues and physical abrasion.

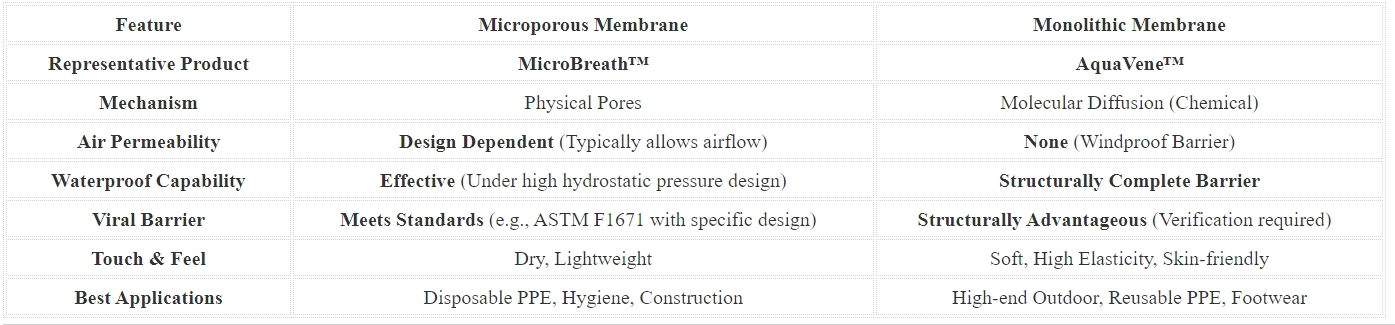

The Critical Showdown — Technical Comparison Table

To help you visualize the differences, we have compiled the following technical comparison:

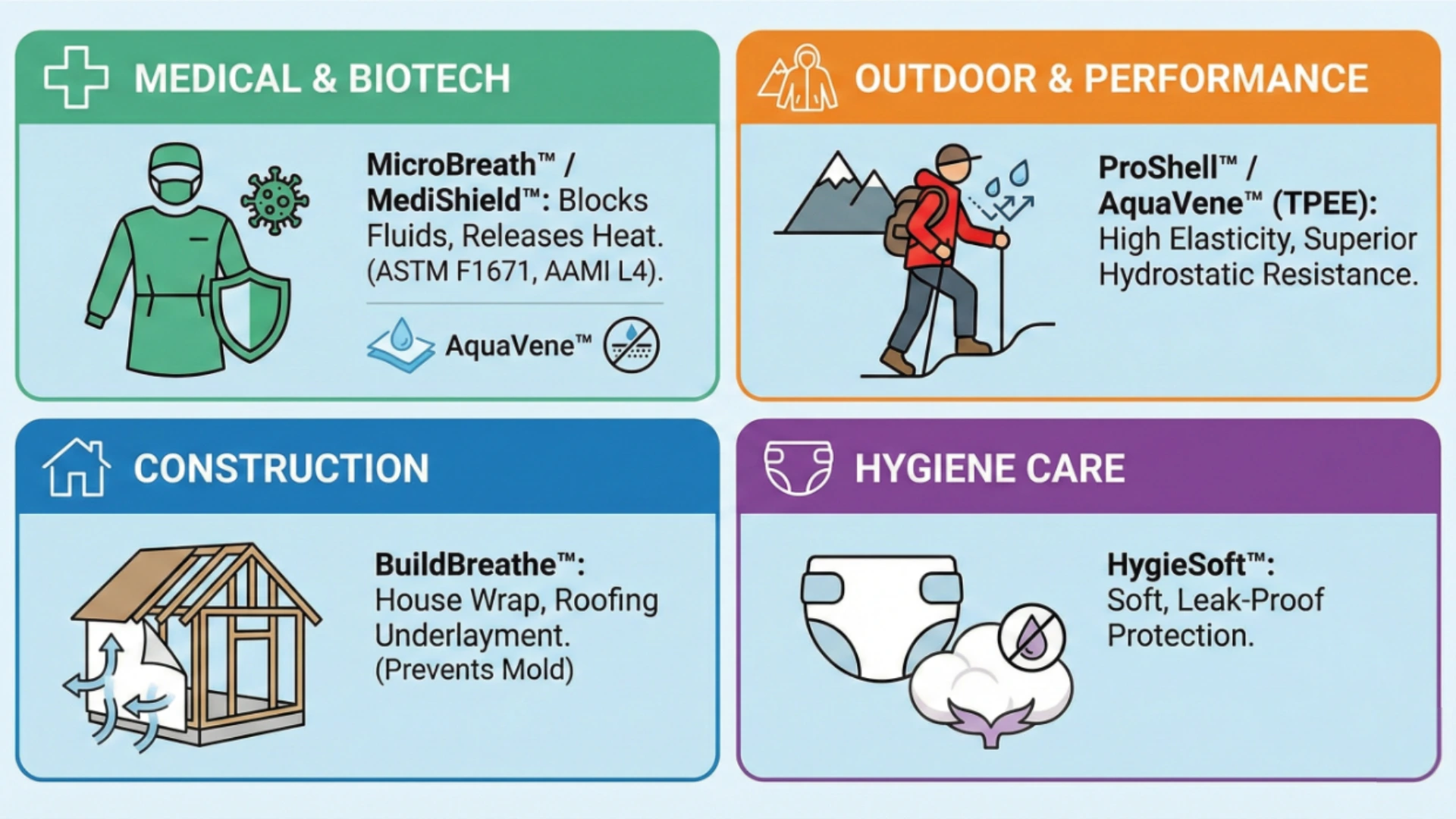

Industry Application Guide — How to Choose?

The choice depends entirely on the problem your end-product needs to solve. Here are expert recommendations from Kae Hwa Industrial for different sectors:

Medical & Biotech

- Demand: Blocking blood and viruses while keeping medical staff comfortable.

- Recommendation:

- MicroBreath™ / MediShield™: For surgical and isolation gowns, the microporous structure effectively blocks fluids and releases body heat. With specific structural designs and testing, it can meet ASTM F1671 and AAMI Level 4 standards.

- AquaVene™: If a higher viral barrier with high mobility is required, the monolithic film is the ideal choice.

Outdoor & Performance

- Demand: Coping with alpine storms and strong winds while allowing for a wide range of motion.

- Recommendation: ProShell™ / AquaVene™. Monolithic membranes (TPEE) possess High Elasticity, stretching with the athlete's movements without breaking, while providing superior hydrostatic pressure resistance.

Construction

- Demand: Houses need to "breathe" to prevent mold inside walls, but must block rain infiltration.

- Recommendation: BuildBreathe™. The microporous structure excels here, ensuring continuous moisture release, serving as a reliable House Wrap and roofing underlayment.

Hygiene Care

- Demand: Diaper and sanitary napkin backsheets requiring ultimate softness and dryness.

- Recommendation: HygieSoft™. Combining microporous film with nonwoven lamination to provide a cotton-like touch and leak-proof protection.

The Kae Hwa Advantage

With many membrane suppliers in the market, why do global brands choose Kae Hwa?

- 0.01 mm Extreme Precision Our Casting Film Technology controls thickness tolerance within ±0.01 mm. This means the MVTR and surface quality of every inch of material are stable and consistent.

-

The Sustainability Promise of Solvent-Free Lamination Kae Hwa employs In-Line Lamination Technology, bonding the film to the fabric immediately after formation.

- Solvent-Free: Eliminates VOC emissions.

- GRS Certified: Providing Global Recycled Standard compliant materials to help you achieve ESG goals.

Elevating Your Product to World-Class Standards

From microscopic pores to molecular diffusion, the world of waterproof breathable technology is both profound and fascinating. MicroBreath™ brings you breath-like airflow, while AquaVene™ provides an indestructible molecular shield.

At Kae Hwa Industrial, we are not just material suppliers; we are your technical consultants. We use 60 years of experience to transform 0.01 mm precision into your product's competitive edge.

Ready to build the perfect invisible shield for your product?

Contact the Kae Hwa R&D Team today for samples and customized solutions!

[👉 Click Here to Start Consulting]

FAQ

Q1: Will microporous membranes leak because of the holes?

A1: Not within the normal design pressure range. This is because liquid water exhibits surface tension, and the diameter of the micropores is far smaller than that of a water droplet. Unless the water pressure exceeds the membrane's Breakthrough Pressure, water cannot penetrate. Kae Hwa's MicroBreath™ series undergoes rigorous testing to ensure excellent waterproof performance.

Q2: Since Monolithic membranes have no holes, why don't they feel stuffy like plastic bags?

A2: This is due to the chemical properties of the "Hydrophilic Polymers." Although air cannot flow directly through, the membrane actively absorbs moisture from the skin's surface and diffuses it outward. This mechanism is particularly efficient when the body sweats, creating a high humidity differential (Dynamic Breathability).

Q3: Which membrane is more eco-friendly?

A3: Both can be environmentally friendly. Kae Hwa offers recyclable PE/PP microporous membranes and TPEE monolithic membranes. More importantly, our manufacturing process uses Solvent-Free Lamination technology and holds GRS Certification, dedicated to reducing carbon footprints.

Q4: Can I request a customized MVTR (Breathability)?

A4: Yes. With 60 years of formulation experience, Kae Hwa Industrial can precisely control pore structures or polymer formulations to customize specific MVTR and hydrostatic pressure specifications for you.