Medical Breathable Fabrics Decoded: Viral Barrier Mechanisms & ASTM F1671 / ISO 16604 Testing Guide

When "Waterproof" Just Isn't Enough

In high-stakes medical and industrial settings, a simple waterproof barrier offers a false sense of security. The real threat to frontline workers isn't visible liquid; it's the microscopic pathogens hiding within it. The engineering challenge is massive: create a shield impenetrable to lethal viruses like Hepatitis B, C, and HIV, but permeable enough to let sweat escape, preventing heat exhaustion and ensuring focus during critical procedures.

This is where material science saves lives.

Viral-barrier breathable fabrics are not standard textiles—they are engineered defense systems. By utilizing advanced microporous and monolithic membrane technologies, Kae Hwa Industrial Co., Ltd. creates barriers with pore structures verified to block bloodborne pathogens (per ASTM F1671 and ISO 16604) while maintaining the breathability critical for long-term wear.

Backed by over 60 years of chemical engineering expertise, Kae Hwa delivers more than just fabric; we deliver peace of mind. This guide serves as a technical resource for procurement officers and QA managers to understand the rigorous physics and testing protocols behind our certified protection.

How Viral-Barrier Breathable Fabrics Work: A Scientific Guide to ASTM F1671 & ISO 16604

Microscopic Science: The Physics of Protection and Breathability

How does a piece of fabric distinguish between a lethal virus and a water vapor molecule? It comes down to precision engineering at the nanometer scale and the manipulation of surface tension.

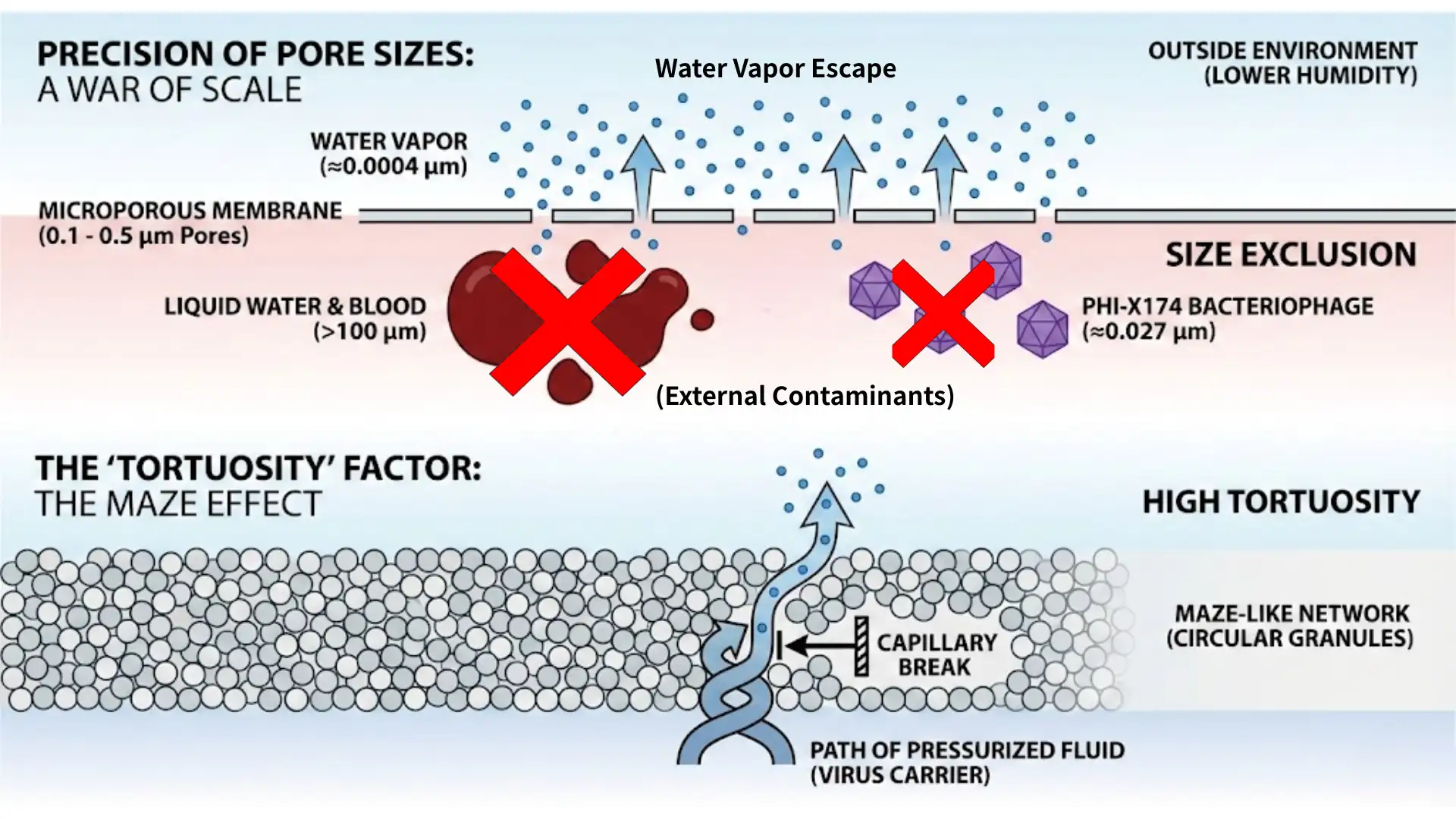

Precision of Pore Sizes: A War of Scale

Our microporous membrane technology operates on a strict physical principle: Size Exclusion. By controlling pore size distribution—typically optimized between 0.1 to 0.5 µm in our manufacturing process—we create a selective barrier that exploits the vast size difference between moisture and pathogens.

Consider the scale: A Water Vapor Molecule is approximately 0.0004 µm. Being a gas, individual molecules are small enough to navigate the membrane's pores freely, driven by the difference in temperature and humidity (partial pressure) between the wearer's skin and the outside environment.

In stark contrast, the Phi-X174 Bacteriophage (Test Virus) is approximately 0.027 µm. While technically smaller than the pore opening, the virus does not travel in a vacuum; it is carried in fluids with surface tension. Liquid Water and Blood droplets are significantly larger (>100 µm), and their high surface tension prevents them from penetrating the sub-micron pores, effectively blocking the viral payload they carry.

The "Tortuosity" Factor: The Maze Effect

It is not just about hole size; it is about the path. Kae Hwa's microporous films are engineered with high tortuosity. This means the pores do not go straight through the film like a tunnel. Instead, they form a complex, twisting, maze-like network within the polymer matrix.

Even if a pressurized fluid containing a virus attempts to enter a pore, it must navigate this chaotic path. The combination of the naturally hydrophobic (water-repelling) nature of our Polypropylene (PP) polymers and this complex structure creates a Capillary Break. This physical phenomenon effectively stops the liquid column—and the viruses it carries—dead in its tracks before it can breach the inner surface.

Dual Technology Paths: Microporous vs. Monolithic

Kae Hwa utilizes two distinct technologies to achieve this filtration, allowing for customized solutions based on the end-use application.

Microporous PP Films rely on physical filtration via tortuous pores. Unlike standard PE films, our specialized PP (Polypropylene) membranes offer enhanced thermal stability and robust barrier properties, making them the industry standard for disposable medical gowns and industrial coveralls (Type 5/6) where high breathability and viral protection are required.

Monolithic TPEE Films, conversely, operate via Solid-State Diffusion. Our Thermoplastic Polyester Elastomer (TPEE) films are solid, non-porous barriers. They transport moisture vapor via molecular diffusion through hydrophilic polymer chains: moisture is absorbed into the film, moves across the polymer matrix, and desorbs on the outer surface. Since there are zero pores, there is zero pathway for viruses, making this technology ideal for high-end reusable surgical gowns or outdoor performance gear where absolute viral barrier integrity and durability against physical stress are paramount.

Analyzing ASTM F1671: The Logic of Verification (US Standard)

.webp)

For the North American market and AAMI PB70 Level 4 Isolation Gown applications, ASTM F1671 is the undisputed gold standard. But why isn't a simple water test enough?

Beyond Liquid Barrier: Why Bacteriophage?

Many fabrics pass ASTM F1670 (Synthetic Blood Penetration), but that is merely a visual test for liquid holdout. It fails to account for the microscopic reality of viral transmission. Blood has a lower surface tension (~42 dynes/cm) than water (~72 dynes/cm), making it harder to repel. Viruses are even more insidious, as they are carried in these low-surface-tension body fluids.

Phi-X174: The Rigorous Surrogate

ASTM F1671 uses the Phi-X174 bacteriophage as a viral surrogate. This choice is deliberate and scientifically rigorous. At just 27 nanometers, Phi-X174 is one of the smallest known viruses—significantly smaller than Hepatitis B (42nm), Hepatitis C (30-60nm), and HIV (approx. 120nm). The logic is undeniable: if Kae Hwa's fabric blocks Phi-X174, it provides a statistical safety margin that effectively covers all larger clinically relevant bloodborne pathogens.

Test Environment Setup

The test is not gentle. It uses a specific test cell where the fabric is challenged with a nutrient broth containing the virus under a dynamic pressure protocol. The material is subjected to atmospheric pressure for 5 minutes, followed by a 2.0 PSI pressure spike for 1 minute to simulate a surgeon leaning against a wet table, and concluding with another 54 minutes at atmospheric pressure.

After the test, the fluid on the "clean" side is assayed. Even a single viral plaque forming in the culture results in a FAILURE. Kae Hwa’s medical-grade laminated materials consistently achieve a PASS, ensuring zero viral breakthrough under these extreme conditions.

Exploring ISO 16604: European Standards & EN 14126

For our European partners, compliance with EN 14126 (Protective clothing against infective agents) is the benchmark. Within this standard, ISO 16604 serves as the critical viral penetration test.

The "B" Designation: Type 4B, 5B, 6B

In Europe, industrial coveralls are categorized by "Type." When a garment passes the rigorous biological tests of EN 14126, a suffix "B" is added (e.g., Type 4B). This tells safety officers that the suit is not just chemical-proof, but bio-hazard proof. To achieve this, Kae Hwa's fabrics must pass a comprehensive battery of tests beyond just ISO 16604, including ISO 22610 (wet bacterial penetration via mechanical friction), ISO 22611 (contaminated aerosols), and ISO 22612 (dry microbial penetration).

The Classification System of ISO 16604

Unlike the US "Pass/Fail" model, ISO 16604 classifies protection levels based on Hydrostatic Pressure. It involves a step-test starting with ISO 16603 (screening with synthetic blood) to find the fabric's pressure limit, followed by ISO 16604 to validate viral barrier integrity at that specific pressure.

Kae Hwa's engineered fabrics are capable of achieving high classifications—ranging from Class 2 (1.75 kPa) up to 13.8 kPa (meeting ASTM F1671 requirements, approximating Class 5 levels)—providing the verified defense required for high-risk biological environments. We continuously challenge the limits to ensure our products meet the stringent requirements for EU Type 4B/5B/6B regulations.

Manufacturing Integrity: Zero Tolerance for Defects

A lab report proves the design is sound, but manufacturing excellence ensures the roll you receive performs as promised. This is where Kae Hwa's 60 years of experience becomes a tangible asset. We employ strict Inline Quality Control (QC) measures to ensure consistency.

Our process includes automated Online Pinhole Detection, where optical scanning systems detect microscopic defects in the membrane during lamination, automatically flagging any section that falls below spec. Simultaneously, we conduct rigorous Adhesion Testing to ensure the bond between the delicate membrane and the durable nonwoven fabric withstands donning, doffing, and active movement. Continuous Hydrostatic Head Monitoring ensures waterproof ratings remain consistent across millions of meters of production.

Balancing Comfort and Compliance

Protection is useless if the wearer removes the gear due to heat stress. A surgeon sweating profusely is at risk of error; an industrial worker overheating is a liability.

We focus on prioritizing WVTR (Water Vapor Transmission Rate) performance to minimize heat stress. Kae Hwa's laminates are specifically engineered for high breathability, facilitating the effective phase change of sweat from liquid to vapor to regulate the wearer's body temperature.

Our engineering team has found the equilibrium, ensuring the tortuosity needed for viral protection while maximizing the porosity needed for breathability. We offer a customized range, from ultra-lightweight 10gsm films for hygiene applications to heavy-duty 100gsm options for industrial use, ensuring wearers remain dry and comfortable during long shifts, significantly reducing the risk of heat exhaustion.

Sustainability in Safety

Modern procurement demands eco-responsibility, and Kae Hwa is at the forefront of sustainable barrier technologies. We utilize Solvent-Free Lamination processes that eliminate the release of Volatile Organic Compounds (VOCs), protecting both the environment and our workers. Furthermore, we offer fabrics certified under the Global Recycled Standard (GRS), utilizing recycled PET bottles to create high-performance nonwovens without compromising viral barrier properties. We also provide PFC-Free options, moving away from harmful long-chain fluorocarbons to offer effective water-repellent solutions that are safe for the planet.

Choose Science-Backed Protection

In critical moments where safety is non-negotiable, rely on data, not just claims. Kae Hwa Industrial Co., Ltd. combines 60 years of manufacturing excellence with certified compliance to ASTM F1671, ISO 16604, and EN 14126.

FAQ

Q: Does passing ASTM F1670 mean the fabric is virus-proof?

A: Absolutely Not. ASTM F1670 only tests for visual penetration of synthetic blood. It cannot detect invisible viruses. A fabric can hold out blood but still allow viruses to pass through its pores. You must specify ASTM F1671 (which Kae Hwa provides) for verified viral protection.

Q: Which is better for my application: Microporous or Monolithic?

A: Both are effective if they pass viral standards, but they serve different needs. Microporous PP is ideal for disposable PPE (Type 5/6 suits, isolation gowns) where cost-efficiency and immediate high breathability are key. Monolithic TPEE is better suited for reusable garments (surgical gowns washed via industrial laundry) or high-durability applications, as the solid film does not degrade or lose barrier properties when stretched or washed.

Q: What is the difference between "Type 4" and "Type 4B"?

A: In European standards, "Type 4" refers to a spray-tight chemical suit. The addition of the suffix "B" (Type 4B) indicates that the material has also passed the biological barrier tests of EN 14126. This includes not only the ISO 16604 viral test but also resistance to wet bacteria (ISO 22610), contaminated aerosols (ISO 22611), and dry microbes (ISO 22612). Kae Hwa provides fabrics suitable for fully compliant Type 4B, 5B, and 6B certification.