Kae Hwa Film Portfolio Overview|Complete Guide to Functional Breathable and Waterproof Films

In the design of functional fabrics and protective materials, films are more than just a waterproof layer—they are the core driver of overall performance.

With decades of experience in membrane development, Kae Hwa Industrial offers proprietary formulations and integrated production capabilities. We provide a wide range of film solutions tailored to different application needs, along with lamination, slitting, and post-processing services to support OEM/ODM clients in rapid product development and scale-up.

This article summarizes the major types of membranes developed by Kae Hwa and their recommended use cases to help you quickly select the ideal material.

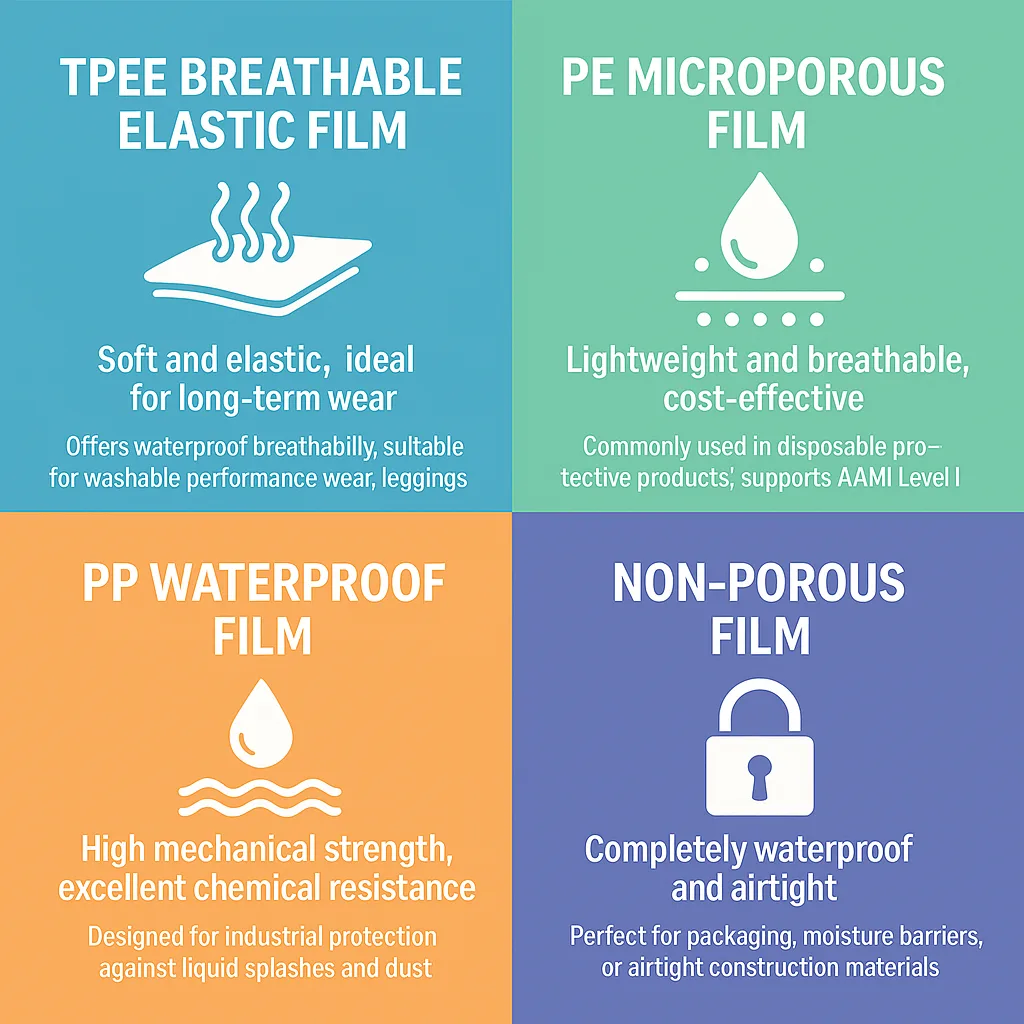

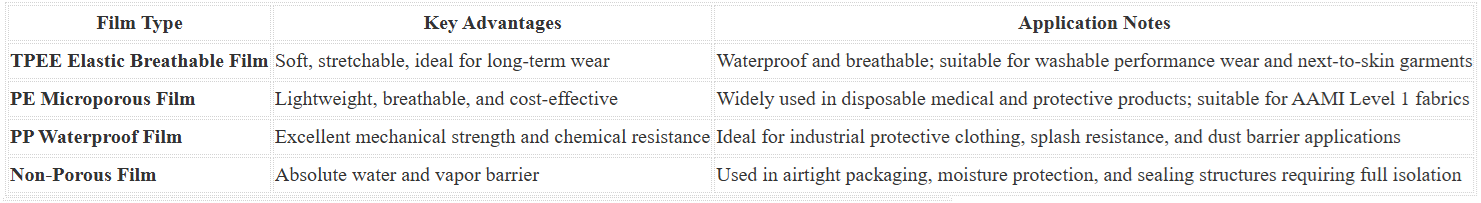

Film Types at a Glance: 4 Core Categories

How to Choose the Right Film? Application-Based Recommendations

🩺 Medical Protection (Primarily Disposable Use)

Recommended: PE Microporous Film, providing basic waterproof and breathable functionality. Commonly used in isolation gowns, protective suits, and other disposable garments.

Supports testing standards:

- AATCC 127 (Hydrostatic Pressure Test)

- ISO 5636-5 (Air Permeability Test)

- EN 14126 (Barrier Performance Against Infective Agents)

🛡️ Industrial Protection (Chemical & Dust Exposure)

Recommended: PP Waterproof Film or PE Film + Surface Coating, offering effective chemical splash resistance and particle barrier protection. Suitable for workwear and chemical-handling garments.

Supports testing standards:

- EN 13034 (Protection Against Liquid Chemicals)

- EN 1149-5 (Antistatic Performance)

👕 Functional Apparel / Washable Use Cases

Recommended: TPEE Elastic Film, combining flexibility, softness, and reliable waterproof performance. Ideal for activewear, waterproof jackets, and garments requiring repeated washing and comfort.

Supports testing standards:

- AATCC 135 (Dimensional Stability After Washing)

- AATCC 127 (Durable Water Resistance)

🏗️ Airtight & Non-Breathable Applications (e.g., Packaging)

Recommended: Non-Porous Film, offering complete water and vapor isolation. Ideal for moisture barrier packaging, air-sealed construction, and high-strength applications.

Certification & Documentation Support

We understand the importance of quality validation and export compliance. Kae Hwa provides full documentation and test reports upon request, including:

- AATCC / ISO / EN Test Reports for waterproofing, antistatic, air permeability, and viral barrier functions

- TDS (Technical Data Sheet)

- COA (Certificate of Analysis)

- MSDS (Material Safety Data Sheet)

Interested in Our Film Selection? Discover More Now!

Kae Hwa offers a diverse and stable range of membranes, including TPEE, PE, PP, non-porous films, breathable membranes, colored films, and printed membranes, all engineered for use in protective, medical, and functional textile applications.

We also provide custom lamination solutions and technical consultation to help OEM/ODM partners build the optimal fabric structure.

🔍 Click to explore more fabric options

Frequently Asked Questions (FAQ)

Q1: What’s the difference between your PE and TPEE films?

A: PE film is designed for single-use applications and offers basic waterproofing, while TPEE film is softer, stretchable, and suitable for repeated washing and long-term wear.

Q2: Do you offer custom lamination services?

A: Yes. We supply both standalone films and multi-layer laminated materials, with structures tailored to your specific needs.

Q3: What certifications do your films support?

A: Our membranes can meet a wide range of global standards, including AATCC 127 (water resistance), EN 1149-5 (antistatic), and EN 14126 (viral barrier protection).

Q4: Can you support international shipping and customs clearance?

A: Absolutely. We can provide all necessary export documents, including TDS, COA, and MSDS.