KaeHwa Protective Fabric Overview: From Material Structure to High-Level Protective Applications

As global awareness of infection control and workplace safety continues to grow, fabric has become the core determinant of both protective performance and wearability—not just a garment component.

Kae Hwa Industrial, a leading manufacturer of breathable membranes and laminated functional textiles in Taiwan, specializes in developing multilayer protective fabrics with structural advantages and global certifications.

From resin formulation to composite lamination, we offer vertically integrated solutions for both medical and industrial protective needs.

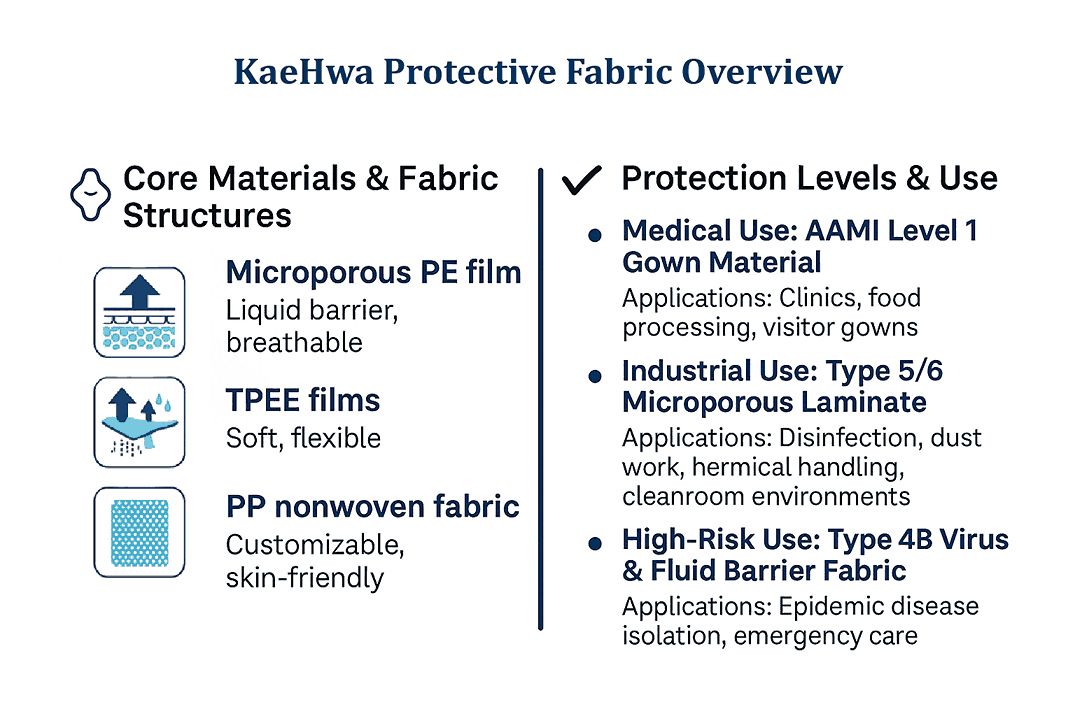

🧪 Core Materials & Fabric Structures

Kae Hwa focuses on porous structures and multilayer lamination technologies to build fabrics for various protection levels. We use the following key materials:

- Microporous PE film: Excellent liquid barrier with breathability, ideal for disposable protective clothing

- TPEE films: High elasticity and softness, suitable for close-contact or long-duration medical wear

- PP nonwoven fabric: Provides structure and stability; customizable with antistatic and skin-friendly treatments

These films can be laminated in single, double, or triple layers to create fabrics with different barrier strengths and wearing comfort.

🛡️ Protection Levels & Use Cases

✅ Medical Use: AAMI Level 1 Gown Material

- Structure: PP nonwoven + polymer coating

- Features: Water-repellent, dust-resistant, lightweight and soft

- Standard: AATCC 42 Impact Penetration ≤ 4.5g

- Applications: Clinics, food processing, visitor gowns

✅ Industrial Use: Type 5/6 Microporous Laminate

- Structure: Microporous PE film + nonwoven

- Features: Liquid barrier, particle protection, antistatic treatment, breathable

- Certifications:

- EN ISO 13982-1 (Type 5)

- EN 13034 (Type 6)

- EN 1149-5

- Applications: Disinfection, dust work, chemical handling, cleanroom environments

💧 See the liquid penetration test here.

✅ High-Risk Use: Type 4B Virus & Fluid Barrier Fabric

- Structure: High-density microporous film + water-repellent nonwoven

- Certified Performance:

- EN 14605:2005+A1:2009 Type 4B

- ISO 16603 Blood Penetration: Class 6

- ISO 16604 Viral Penetration: Class 2

- ISO 22611 Liquid Aerosol Penetration: Class 3

- Applications:

- Epidemic control, emergency rooms, infectious disease isolation, global tenders

🔎 Click to explore the full feature breakdown.

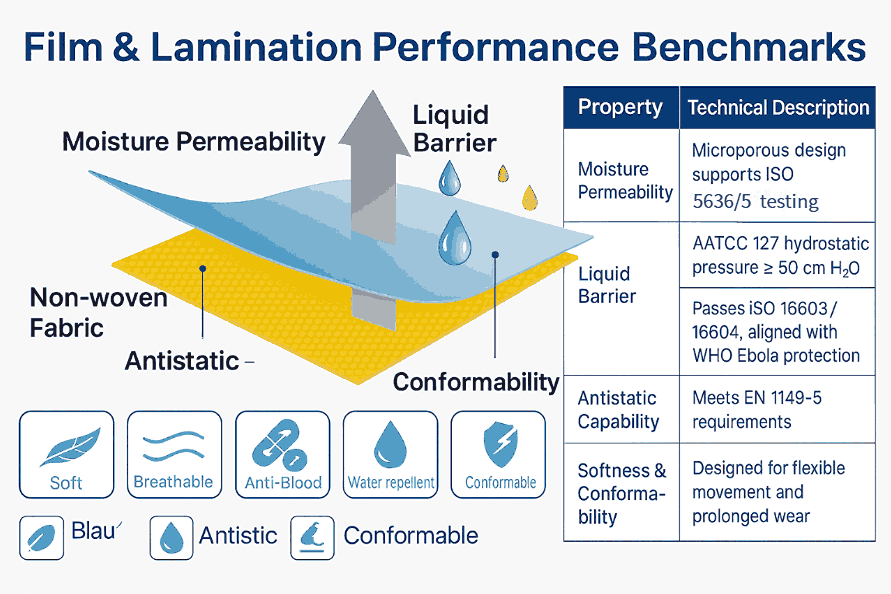

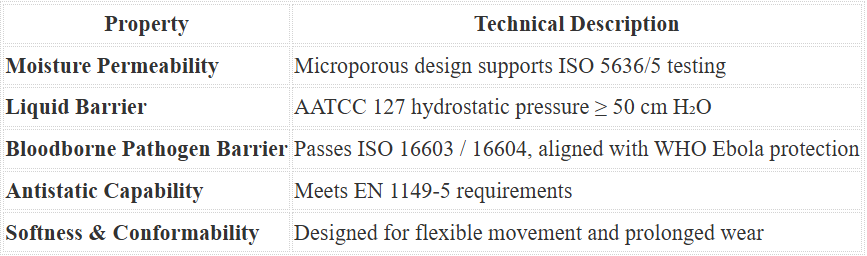

🔬 Film & Lamination Performance Benchmarks

🧩 Flexible Manufacturing & Extended Applications

We offer customizable options to support different processing and usage needs:

- Film Resins: Primarily microporous PE and PP membranes; TPEE used for selected cases

- Grammage Range: 43 gsm to 70 gsm

- Structure Layers: 1–3 layer lamination (including nonwoven composites)

- Special Functional Treatments: Antistatic, skin-friendly, anti-fog, washable, printable, etc.

Applications Include:

- Medical isolation gowns / healthcare uniforms

- Disposable protective suits for epidemic response

- Industrial suits for paint, cleaning, and chemical tasks

🌐 Certified Production & Global Supply Support

Kae Hwa supports OEM and brand clients with reliable production capacity. All products follow ISO quality systems and are backed by full export-ready documentation (TDS, MSDS, COA).

We also assist in coordinating third-party testing to obtain required CE, FDA, or international certifications.

🔍 Interested in our certified protective fabrics? Learn more here.

🧾 Frequently Asked Questions (FAQ)

Q1: What’s the difference between AAMI Level 1 and Type 5/6 fabrics?

A: AAMI Level 1 is for light medical isolation with splash protection; Type 5/6 is for industrial use, providing higher resistance to dust and light chemical sprays.

Q2: What certifications do Kae Hwa fabrics support?

A: Our fabrics meet AATCC 42/127, ISO 16603/16604, EN 14126, EN 14605 Type 4B, EN 13982 Type 5, EN 13034 Type 6, and EN 1149-5.

Q3: Are these fabrics reusable?

A: Most fabrics are designed for single use. For reuse cases, washable structures can be evaluated and developed.

Q4: Can Kae Hwa membranes be laminated to our existing nonwoven?

A: Yes. We offer film supply, lamination service, and technical transfer to help integrate into your existing production line.