Kae Hwa Protective Fabric Performance: Where Full Protection Meets True Comfort

In high-risk environments such as healthcare, industrial operations, or epidemic control, protective clothing is more than just a physical barrier—it's your first line of defense. A truly effective protective fabric must deliver on barrier protection, comfort, breathability, and durability to support frontline professionals over long periods of wear.

As a leading Taiwanese manufacturer of breathable membranes and functional laminated fabrics, Kae Hwa Industrial offers a wide range of high-performance protective textiles used in medical gowns, disposable coveralls, and industrial suits. Our materials are tested to international standards and trusted by global clients for their protective applications.

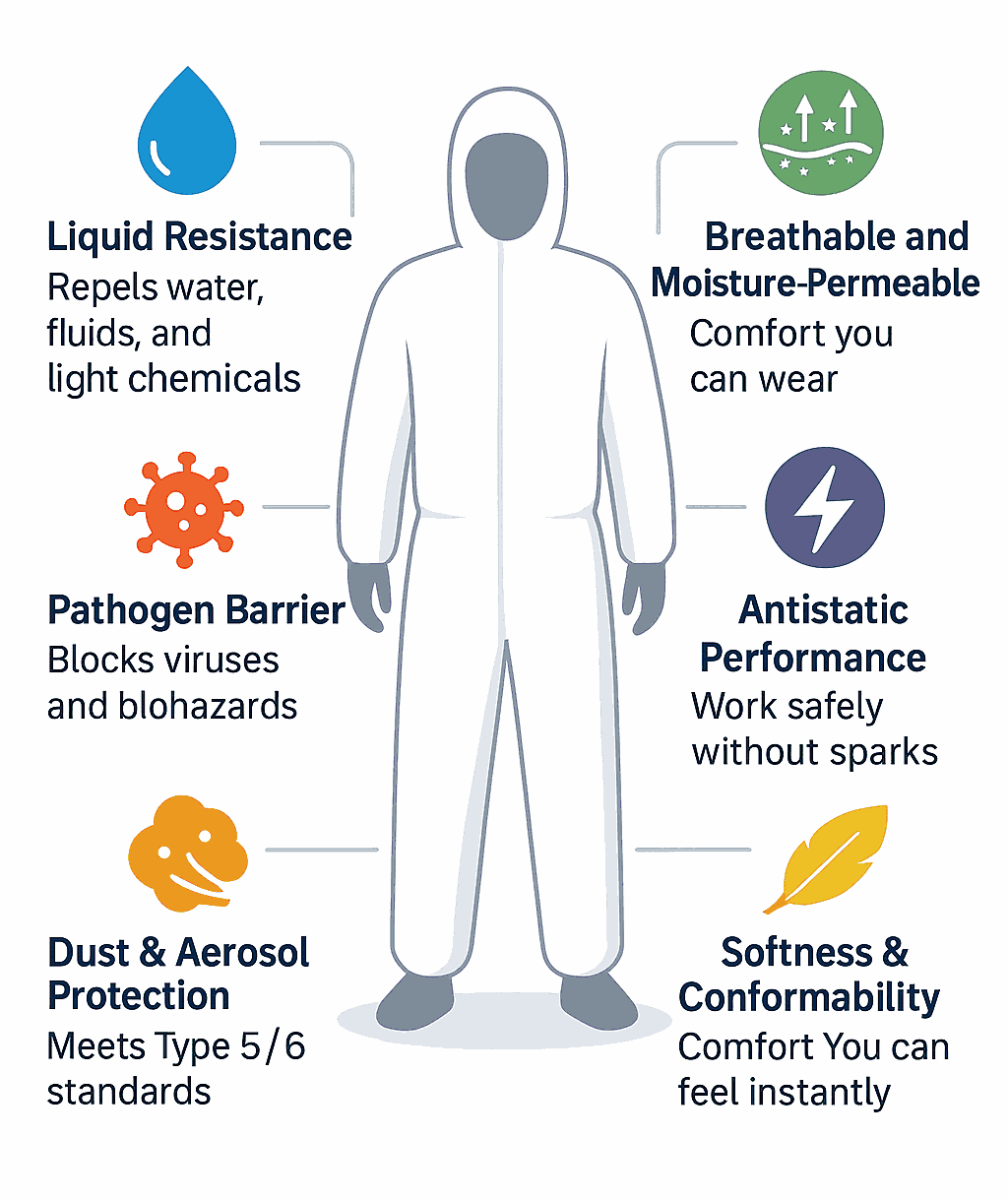

🛡️ All-in-One Protection—Not Just a Barrier, But an Upgrade in Safety!

✅ Liquid Resistance|Repels Water, Fluids, and Light Chemicals

- Engineered with microporous PE film to block water droplets, body fluids, and low-concentration chemical splashes

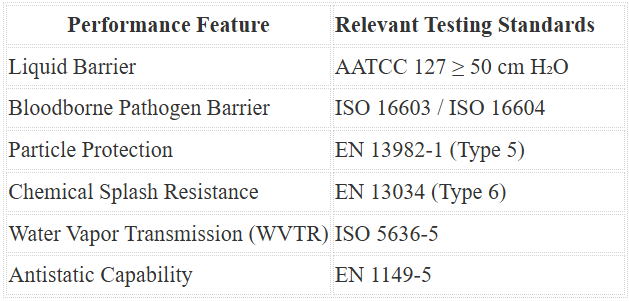

- Meets AATCC 127 standard with ≥ 50 cm H₂O hydrostatic pressure

✅ Pathogen Barrier|Blocks Viruses and Biohazards

- Certified under ISO 16603 / ISO 16604 (aligned with WHO Ebola protection standards)

- Provides protection against blood-borne pathogens and infectious micro-particles

✅ Dust & Aerosol Protection|Meets Type 5 / 6 Standards

- Shields against airborne particulates and light liquid sprays

- Ideal for disinfection, painting, cleaning, and lab environments

✅ Breathable and Moisture-Permeable|Comfort You Can Wear

- Microporous structure allows vapor to escape but blocks liquid

- Supports ISO 5636-5 for air permeability and helps reduce overheating and sweat accumulation

✅ Antistatic Performance|Work Safely Without Sparks

- Complies with EN 1149-5 anti-static standards

- Reduces electrostatic buildup and risk of dust adhesion or spark ignition

✅ Softness & Conformability|Comfort You Can Feel Instantly

- Flexible, skin-friendly fabric that doesn't restrict movement

- Ergonomic fit with no pressure points—great for long shifts

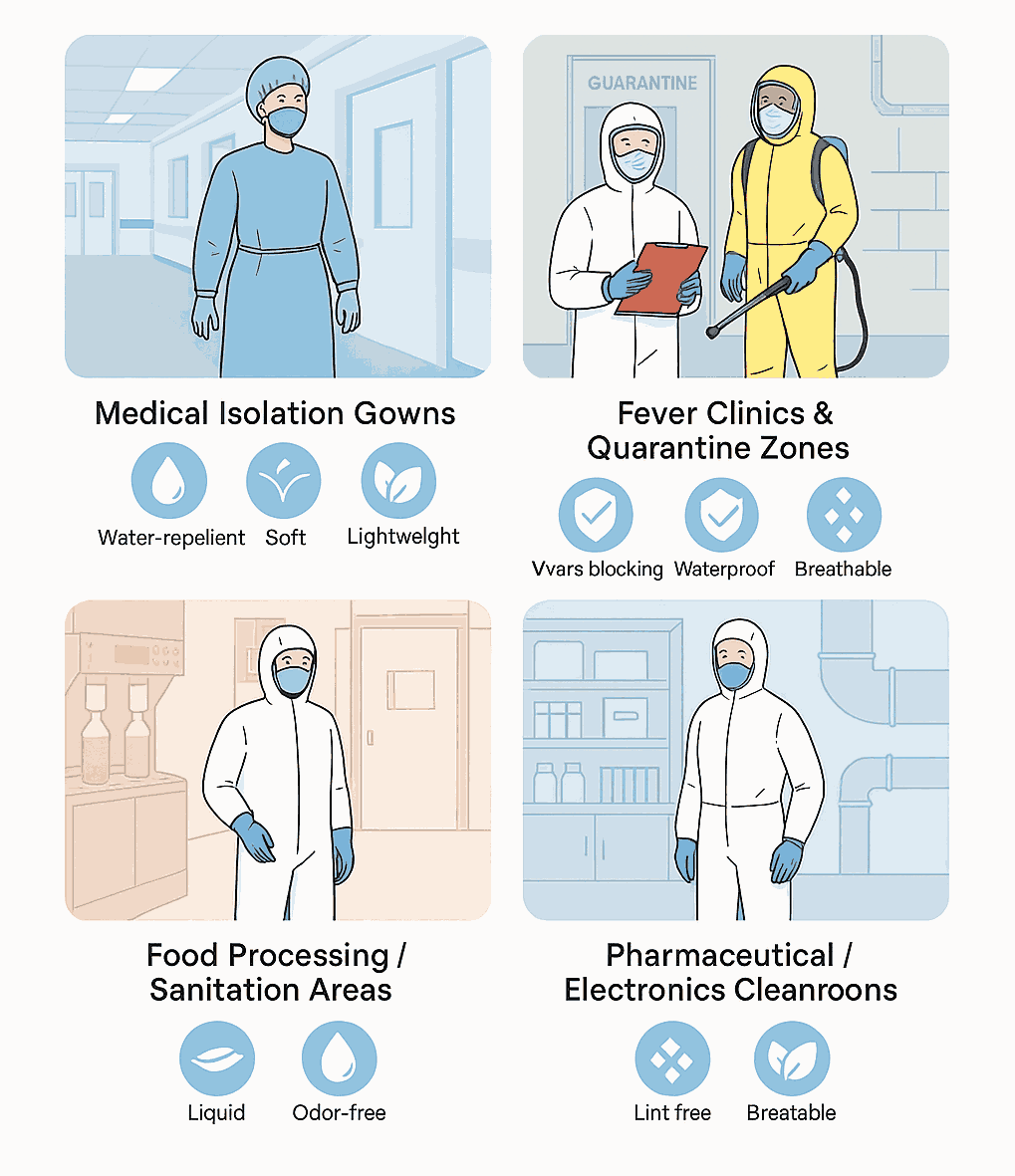

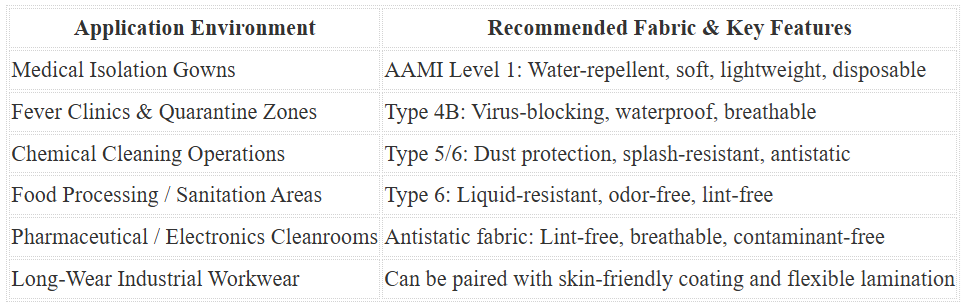

🧪 Practical Applications: When Functionality Meets Real-World Needs

🔬 Measurable Performance Backed by International Testing

🏭 Flexible Manufacturing—Supporting OEM & Custom Functional Fabrics

Kae Hwa offers high-flexibility film coating and lamination services to support your custom development needs:

- Membrane Types: Microporous PE, TPEE

- Grammage Options: 43gsm–70gsm

- Structure Choices: Single-layer / double-layer / triple-layer composites

- Functional Treatments: Antistatic, skin-friendly, anti-fog, washable, printable

Applicable to:

☑ Medical Gowns

☑ Type 5/6 Industrial Coveralls

☑ Type 4B Pandemic Protection Suits

☑ OEM/ODM Lamination Services

✅Click to view our protective coveralls!

🌐 Global Certifications & Reliable Supply

- ISO-certified manufacturing systems

- Full technical documentation available: TDS / MSDS / COA

- Assistance with CE / FDA / EN testing and compliance

🧪 Learn more about our test procedures and results here.

🧾 Frequently Asked Questions (FAQ)

Q1: What's the difference between Type 5/6 fabric and medical-grade fabric?

A: Type 5/6 fabrics are for industrial use and offer higher protection against airborne dust and light chemical sprays, compared to basic medical isolation gowns like AAMI Level 1.

Q2: Can your fabric be both waterproof and breathable?

A: Yes! Our microporous structure allows moisture vapor to escape while preventing liquids from passing through—keeping you dry and protected.

Q3: Are these protective fabrics reusable after washing?

A: Most are designed for single-use. However, we also offer washable-compatible laminates upon request.

Q4: Can Kae Hwa membrane be laminated with our in-house nonwoven fabric?

A: Absolutely. We support membrane supply, OEM lamination, and technical consultation to help you integrate with your existing equipment.